Introduction

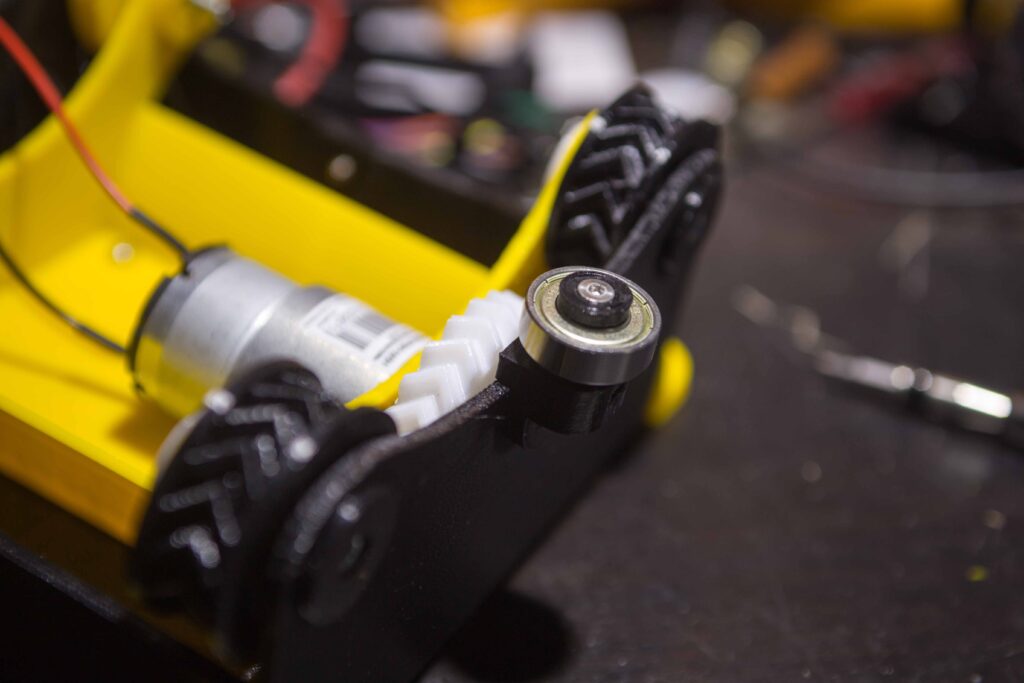

After prolonged operation of my sand polisher, the problem of the glass jumping off the guide gears due to the axially opposing force occurred again and again. As a result, the gear ring is no longer in the groove and the drive gear slips. Prolonged and unattended operation is thus excluded.

To solve this problem I have thought of two designs. One is a bearing that presses along the axis of rotation on the bottom of the glass to prevent it from slipping backwards. On the other hand a bracket which encloses the whole glass and presses (via two bearings) the glass against the gear wheels.

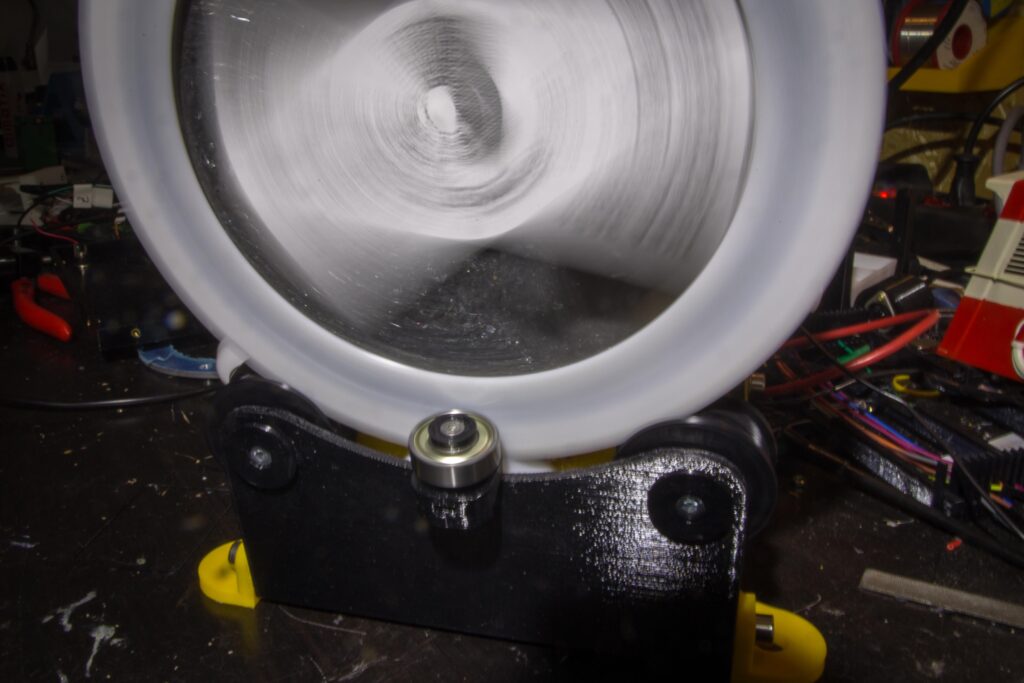

Counter bearing

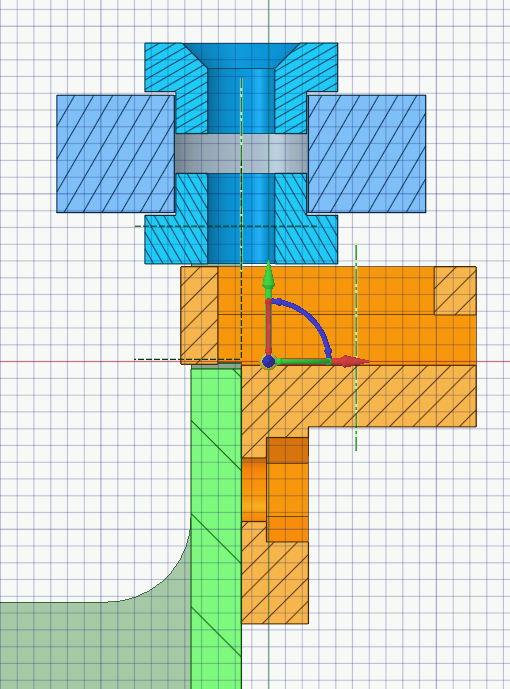

I have designed a holder for a counter bearing with 608 ZZ ball bearing that can be easily attached to the housing afterwards provided bei user Reittec.

The position of the ball bearing and thus the counterpressure can be flexibly adjusted via a slotted hole.

2x M3 x 20 mm countersunk screws and 2x M3 nuts are required for mounting.

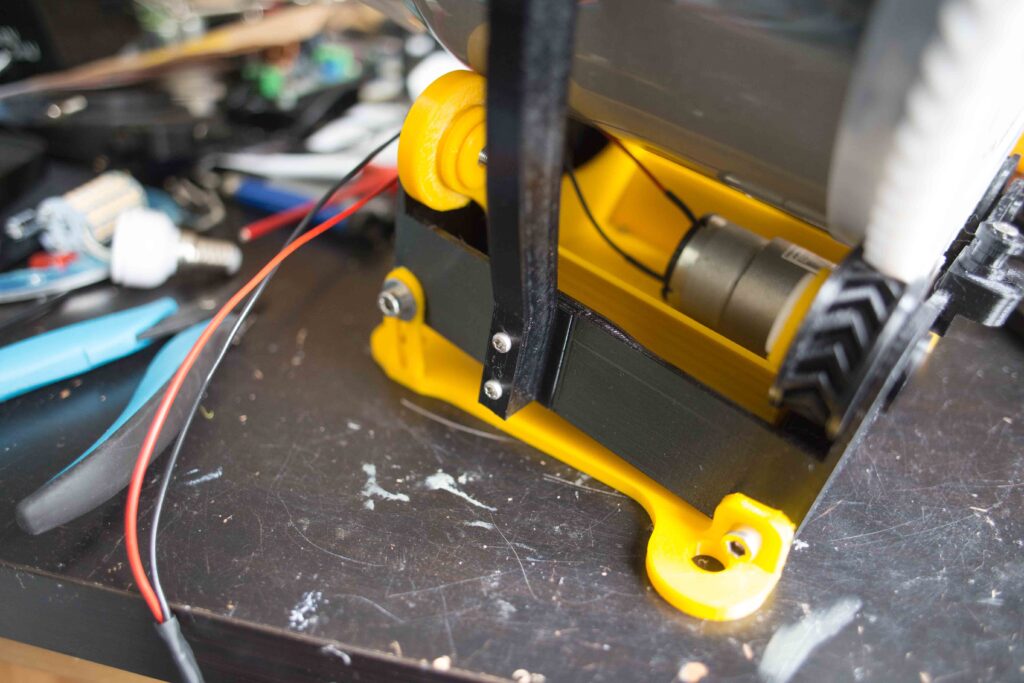

Frame

Unfortunately, this does not completely solve the problem. Slipping is prevented, but now the glass can lift upwards out of the guide gears. So you have to create a counterforce downwards.

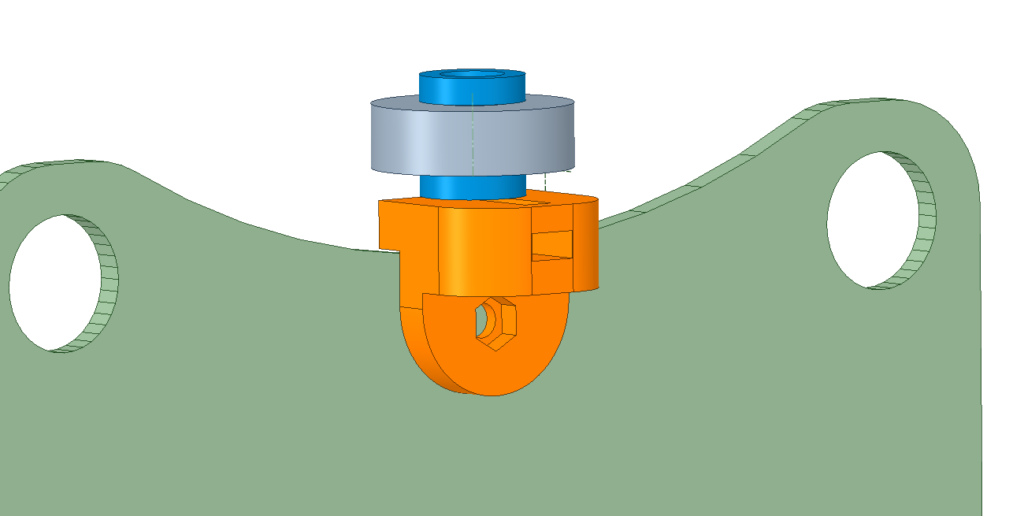

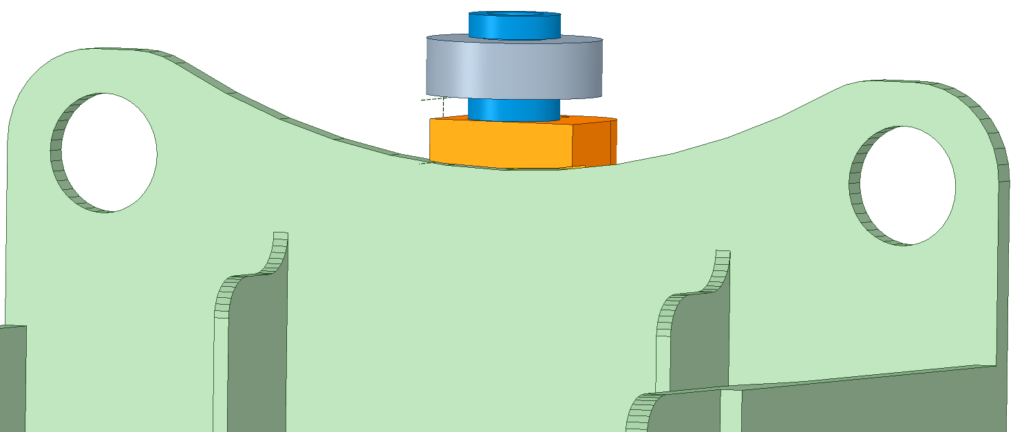

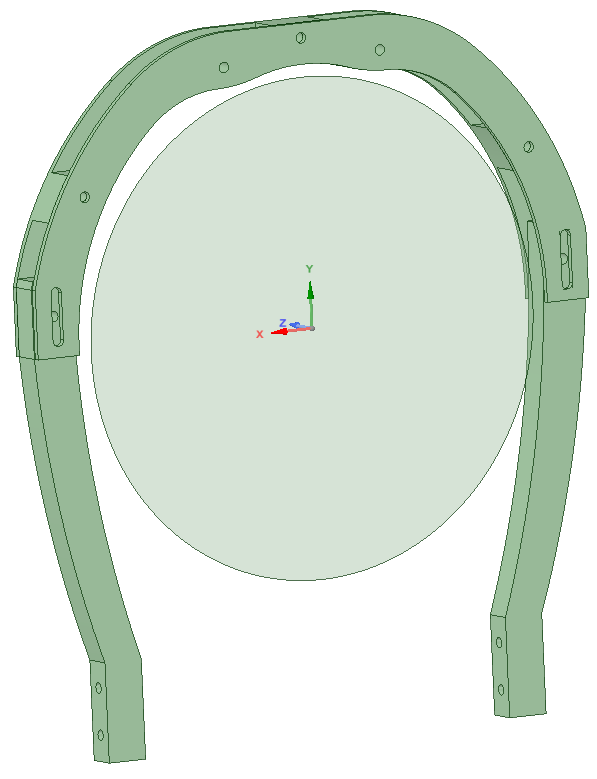

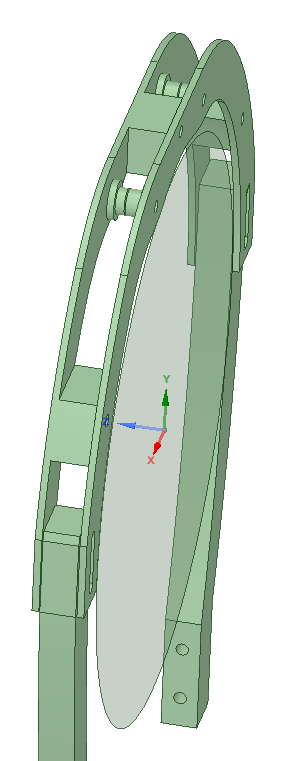

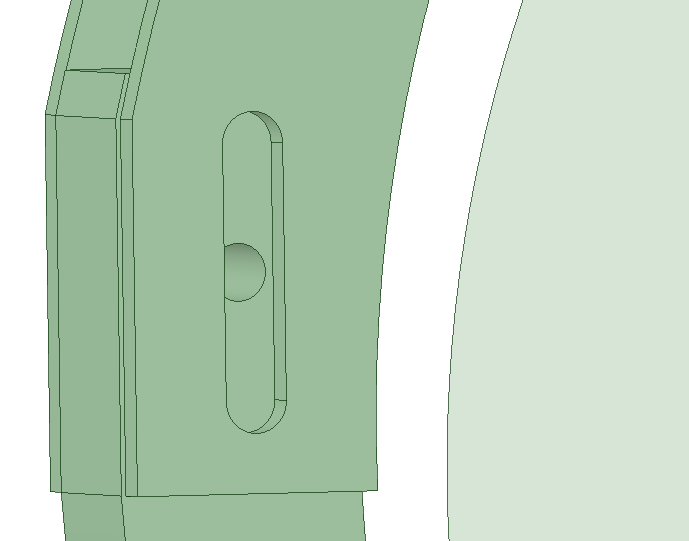

I have designed a bracket with two 608 zz bearings that fits the already existing mounting points of reittecs housing. The height and thus the contact pressure can be varied via two slotted holes. This seems to have solved both problems once and for all.

I have designed the bracket specifically for the 170 mm version of the IKEA glass. The upper part consists of two halves between the 608 ZZ bearings are placed. The upper part is held together with 5x M3 x 20 mm cylinder head screws. In the design, I tried to find a balance between the flexibility of the construction and the stiffness in order to prevent fatigue fractures. The two supports for the bracket are attached directly to the outer part of the housing. I have chosen the mounting points so that the originally intended four holes to connect the two halves of the housing can still be used for this purpose. 4x M3 x 25 mm, 4x M3 washers and 4x M3 self-locking nuts are needed here for fastening. The upper bracket can be attached to the two supports via two slotted holes. The contact pressure can be variably changed via this.

Material